The Sonic Boom in Ultra-Small Ultrasound

The days of going to a special medical facility for an ultrasound exam are numbered. A recent Global Industry Analysts report predicts the global market for medical ultrasound equipment will reach US $6.9 billion by 2017. Embedded developers should note that a lot of this growth will occur in new segments such as portable and handheld ultrasonic devices for emergency medicine, teleconsultation, and clinics. The race is on to develop ultra-small ultrasound devices providing high quality imagery, back-end connectivity, and long battery life—all in a rugged design.

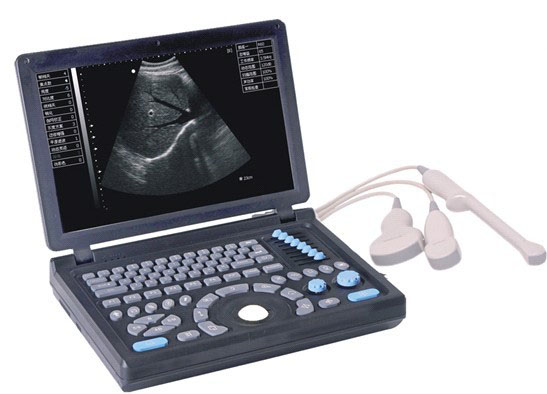

A major category for this boom will be portable B-mode ultrasonic devices (see Figure 1). B-mode ultrasonic devices direct discrete pulses of high-intensity ultrasound at body tissues and then listen for discrete echoes back to create two-dimensional (2D) images displayed on a screen. While imaging quality is lower quality than high-end 3D ultrasound devices, portable B-mode ultrasound devices are very effective in the hands of experienced examiners. Portable ultrasound devices can be used to visualize organs for abdominal, urinary bladder, cardiac, obstetric and pediatric exams. By helping to speed diagnoses, portable ultrasound devices can reduce patient wait times and help healthcare providers deliver faster, more efficient patient care with fewer referrals.

Figure 1. Example of a configuration for a ultra-small B-mode ultrasound device.

A B-mode ultrasound device uses a transducer that emits sounds waves to image body tissues. As each sound wave is reflected back to the transducer, the ultrasound machine needs to calculate the distance that the sound wave traveled between the transducer and tissue using a mathematical equation based on the average speed of sound in tissue and the time it actually took for the relection to return to the transducer. At the core of an ultrasound system is an analog-to-digital converter which converts the filtered input signals from the analog front end into a digital representation which can then be passed to a digital beam former for further processing. Within the beam former the digitized signal is scaled and time delayed to create the focusing effect in the receive chain. The properly adjusted signals are then summed together across all receive channels and passed to the imaging system for rendering and display.

Let's look at what you need to compete in this new category. Compared with previous generations, today's medical ultrasound systems are smaller and lighter with higher levels of processing capability. For developers, the mobile B-mode ultrasonic space presents a number of challenges:

· Small form factor

· Ability to offload FPGA functions to CPU to save power

· High resolution graphics and video

· 24 hours of standby time with 4 hours of working time between charges

· Ability to wake from sleep quickly so as not to keep staff or patients waiting

· Shock/impact resistance

· 24-bit LVDS, VGA, TV-Out display output

· Competitive pricing environment because of pressures in the healthcare industry to reduce costs

To meet these requirements, developers need to source embedded boards, interface components, amplifiers, and analog-to-digital converter (ADC) and digital-to-analog converter (DAC) components that deliver high speeds, improved electrical performance, and lower power consumption, all at reasonable cost. A good place for design teams to start is selecting the processor architecture that enables low-cost, a small form factor configuration with minimum number of extra components.

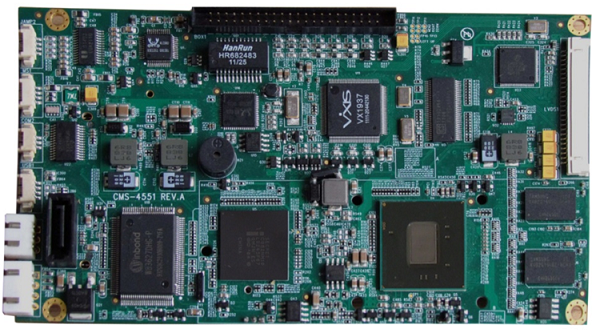

Shenzhen Yacoo Technology Co., Ltd., a general member of the Intel® Embedded Alliance, is targeting this market by providing designers with a rugged, flexible COM board (see Figure 2) that uses an Intel® Atom™ processor N2000 series to meet all the necessary criteria.

Figure 2. The 146mm x 80mm Shenzhen CMS-4551 COM board is expressly designed for the portable B-mode ultrasound device market.

The 146mm x 80mm Shenzhen CMS-4551 COM board aptly meets small form factor requirements and is engineered with a multi-function interface. This enables designers to design their own interface card for the board and use it to differentiate their scanner with their own combination of external I/O (LAN, LDVS, VGA, TV-Out, USB*2, COM1) and positioning of I/O on the product shell.

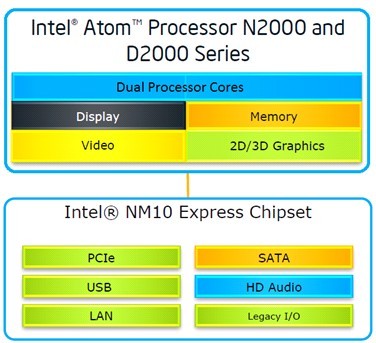

The key to low power is the Intel® Atom™ processor N2000 series (see Figure 3). It takes care of a lot of the computation and graphics processing. Its leading-edge 32nm technology adds new features to a dual-core Intel Atom processor, making it well suited to the needs of battery-operated portable medical devices. Its architectural enhancements enable it to share part of the traditional work performed by the FPGA, including floating-point arithmetic and image processing capability. In fact, its new graphics core delivers up to 2x the performance of previous generation Intel Atom processors, as well as the ability to decode 1080p HD video. The new Intel® Integrated Graphics Media Accelerator 3600/3650 even opens the door to providing the color imagery of high-end ultrasound devices. Plus, dual-display support enables simultaneous viewing on two displays, making it easier for ultrasound technicians to share high-resolution scans with patients on large displays in clinic settings.

Figure 3. The Intel® Atom™ processor N2000 series features high performance integrated graphics, dual HD display support, and power-saving 32nm technology

All this performance comes without a performance penalty. The Intel Atom processor N2000 series is specified for thermal design power (TDP) as low as 3.5 W, when operating with a 1.6 GHz core clock speed and 400 MHz graphics speed. What's more, a new S6 deep-sleep mode consumes just one tenth of the power needed in S5 mode, enabling weeks-long standby time – a key requirement for ultra-small ultrasound.

A new feature, Intel® Rapid Start Technology, helps preserve battery like while enabling devices to quickly resume operation from a deep sleep state when it comes time to do a scan. This technology can move DRAM data to a Flash solid-state drive (SSD) after a user-defined period of time in Standby (S3) mode, putting the system into the Hibernate (S4) state while the OS remains on Standby. When a user turns the device back on, data is quickly transferred back to DRAM and regular operation restored. You get the best of both worlds—longer battery life, plus fast resume.

The CMS-4551 can include up to 2GB DDR3 667MHz memory. All internal interfaces use shock-resistant wafer connectors with latches that are designed to withstand the normal vibration and bumps of a portable ultrasound device. While the low power dissipation of the Intel Atom processors enable fanless designs, for designs requiring fans for other components, the CMS-4551 includes smart-fan technology. This technology detects enivronment temperature and runs the fan only when needed and at the lowest possible speeds to save energy and reduce noise.

Already, three Chinese ultrasound manufacturers are designing systems with the CMS 4551 board—Wuxi Xoamgsjeng Medical Imaging Ltd., Shenzhen Ruike Cable Technology Ltd., and Sichuan Kang Medical Equipment Ltd.

What are your thoughts on the sonic boom in ultra-small ultrasound? Is this yet another promising sign on the way to trimming healthcare costs while improving diagnosis and patient care through portable, connected devices?